Comparative Analysis of SOx Emission-Compliant Options for Marine Vessels from Environmental Perspective

Abstract

With growing concerns over air pollutions attributed to shipping activities, the international maritime organization has enacted a series of stringent regulations. In particular, MARPOL Annex IV Reg. 16 requires sulfur contents from exhaust gases of marine engines to be progressively reduced. To comply with this regulation, three feasible options have been introduced: using LNG as a marine fuel, using heavy fuel oil with the scrubber system, and using the marine gas oil (a type of low sulfur fuel oil). For the objectives of this paper, the holistic environmental impacts pertinent to these options were investigated and compared in ways that the flows of energy and emission were tracked and quantified through the life cycle of the ship. Research findings obtained from a case study with a large bulk carrier showed that the use of the scrubber system to purify heavy fuel oil would produce relatively fewer amounts of emissions attributing to global warming than other two options. On the other than, the use of LNG would be the way to operate the ship in a cleaner way in terms of reducing the acidification, eutrophication, and photochemical effects. Throughout the analysis, the excellence of life cycle assessment was proven to shift the environmental impact of marine systems from the short-term view to the long-term one.

Keywords:

Life cycle assessment, LCA, LNG fuel, Scrubber system, MGO1. Introduction

1.1 background

While about 80% of the world trade relies on the maritime transportation1), in terms of the marine energy sources, the years leading up to now have been a heady time for solid fossil fuels and liquid petroleum products. It was because they were richer, more accessible as well as less expensive than other types of energy sources.

Conventional fuels contain high levels of impurities such as carbon residues, asphalt, and sulfur/metallic compounds that are converted into air pollutants when burned. As a result, the seaborne-trade has attributed to approximately 2.2% of carbon dioxide (CO2), 13% and 12% of nitrous oxides (NOx) and sulfur oxides (SOx) in globe.2)

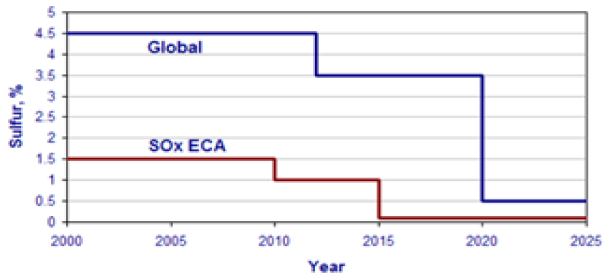

With the worldwide green shipping movement, IMO MARPOL Annex VI, firstly adopted in 1997, has been updated to limit such marine air pollutants. To be specific, the Regulation 14 of the MARPOL Annex VI requires a progressive reduction in SOx from the exhaust gases produced by ship operation, presenting a series of steps for accelerating sulfur limits as described in Fig. 1.

The regulation prompted ship operators to strive to seek for SOx emission-compliant options, urging them to abandon the use of heavy fuel oils (HFOs) that exceed the restricted levels of sulfur contents. At present, three viable options have been introduced: using marine gas oil (MGO), keeping the use of HFO with the scrubber system, and using LNG as an alternative fuel3).

1.2 Description of the SOx emissioncompliant options

The use of MGO for the ships engaged in the service route including emission control area (ECA) have been common since 2015 as it was perceived the easiest way where system retrofitting would be unnecessary, while the logistics of such oils were widely available across ports4). However, economic burdens caused by high prices of MGO on ship owners are considered its drawback.

The scrubber system with which exhaust gases from engines are clean with the fresh water mixed with caustic soda (NaOH) is known to reduce the SOx to 98%.5)

Technical advancement in gas engines, as well as the surge in US shale gas, have supported LNG-fuelled ships to become an immediate prospect.6,7) Like the MGO, LNG has a very low sulfur content, which reduces the SOx concentration of the exhaust gas to a negligible level8).

1.3 Study aim and objectives

Although all the options are effective in reducing SOx emission during the ship operation phase, little discussion and research on the environmental impact of these options in the holistic point of view have been introduced. Similarly, the absence of objective guidelines and experiences makes stockholders poorly informed of the level of their contributions to cleaner shipping activities overall.

To remedy this problem, the range of evaluating environmental effect of those systems may be necessary to be expanded throughout the life cycle of these options.

In this context, this paper was to investigate the holistic environmental impacts of the proposed options, using life cycle assessment (LCA) method by implementing a case study with a deep sea-going bulk carrier. Therefore, this paper was finally to provide insights to decision-makers seeking for better options.

2. Approach adopted

2.1 Introduction to LCA

LCA can be described as a cradle-to-grave approach to assessing the environmental impact of products and manufacturing processes. This assessment is to track the emissions involved in the life stages of a product and to quantify them, which may begin with the production of raw material while ending up with the scrapping of the product. International Organization for Standardization (ISO) has introduced the primary process of LCA9,10).

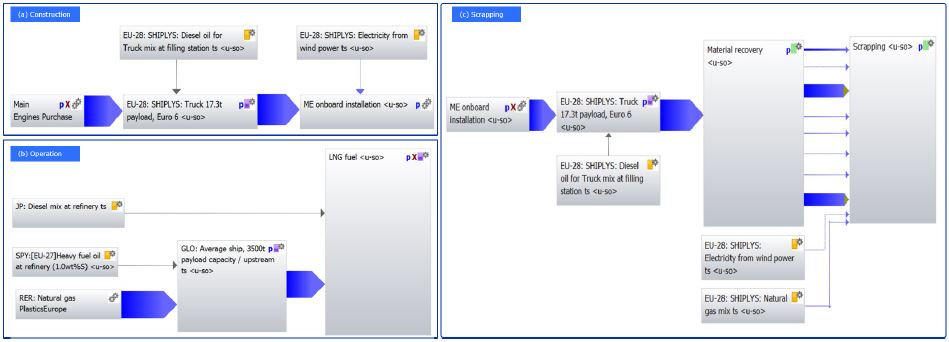

Fig. 2 shows the life cycle of a marine system, which can be expressed as the following stages: construction, operation, and scrapping.

Due to relatively little environmental impact11), the maintenance phase is not considered in this paper.

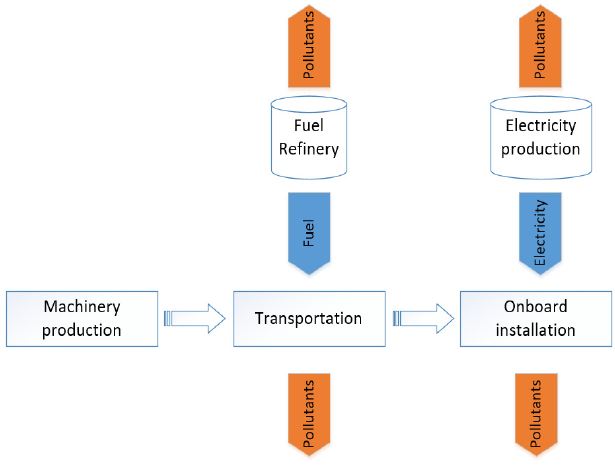

2.2 Construction

The construction stage of a marine system may need to set out from the extraction of raw material to end up with onboard installation via various processes such as transportation, manufacturing, assembly, and commissioning. However, given the purpose of this study to compare the three SOx emission-compliant options, this paper has set a boundary of working scope for the construction stage where begins with the product produced in the manufacturing factory, transportation and finally the onboard installation. Throughout the process, the energy consumption and subsequent emissions were tracked. Fig. 3 outlines the flow of construction stage of the marine system.

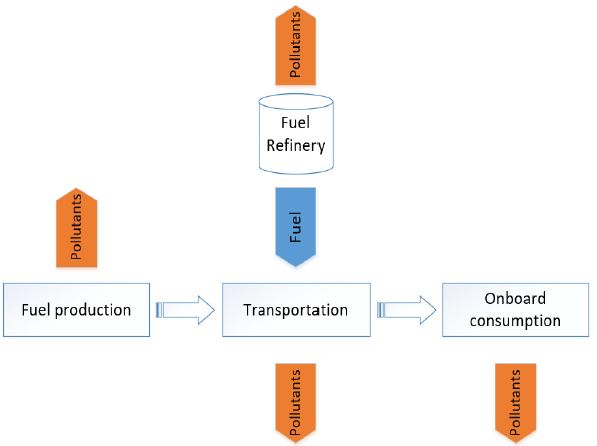

2.3 Operation

The process of the operational stage is shown in Fig. 4. Given that the environmental impact engaged in the operation stage for the marine system largely relies on the fuel consumption, the processes of fuel production, transportation and onboard use are considered for LCA.

The fuel consumption that determines the amount of emissions generated by exhaust gas is calculated based on the ship specifications and operational profiles that will be described in the following section. Table 1 presents the association between the fuel consumption and emissions2).

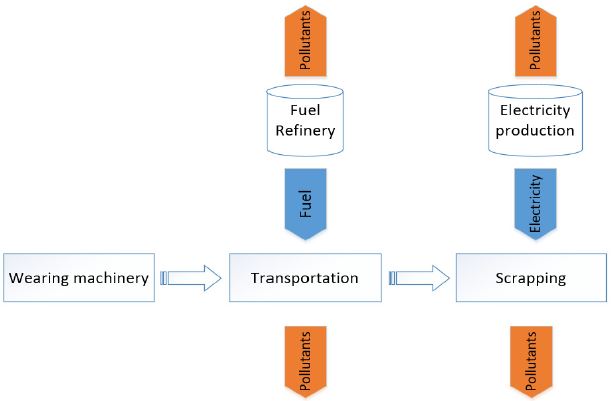

2.4 Scrapping

As shown in Fig. 5, the scrapping process represents the dissembling and disposal of the marine system from the ship.

Throughout this process, electricity is consumed, thereby emissions are produced.

Types of pollutants produced by the scrapping process rely on several factors such as material types to be scrapped and their weights. This paper adopted the material data for a marine engine, provided by the manufacture. Generally speaking, it consists of cast iron (69.5%), steel (21.3%), of aluminum (2.7%), carbon (2.2%), and chrome and tin (1-4%).

Table 2 summarizes the energy consumption and the emission production used for the scrapping of various materials.

3. Case study

3.1 Description of case ship

The selected case ship was a large bulk carrier with 200,000 dead weight tonnage (DWT) engaged in the regular service route between Qingdao, China and Vitoria, Brazil (11,058 nautical miles in return). With an average speed of 15 knots, one voyage can be estimated at 30.7 days. Assuming two weeks per year are out of service for maintenance, this ship is engaged in the service for 46 weeks annually. It was also assumed that three days would be spent for cargo loading and the equivalent time is spent for the un-loading at the port. In addition, another two weeks are spent for dry docking for every 2.5 years. Given the 25 years of the ship lifespan, the total of 1,180 weeks was assumed to be used for ship operation, indicating 225 trips in total.

3.2 Engine specification

The machinery system for each option is described as follows:

MAN B&W 6S70ME (diesel engine) with the capacity of 19,260 kW was selected as the basic engine model. Therefore, the proposed options are described as below:

- Option 1: diesel engine using low sulfur fuel oil (MAN B&W 6S70ME)

- Option 2: diesel engine using heavy fuel oil with scrubber system (MAN B&W 6S70ME and scrubber system)

- Option 3: dual fuel engine using the gas mode only running in natural gas (MAN B&W 6S70ME-GI)

For Option 1 & 2, the engines were to run in diesel oil with 85% engine load at which the specific fuel consumption (SFOC) was given to 169 g/kWh. Meanwhile, for Option 3, the engine was to run in natural gas with 85% engine load at which the specific gas oil consumption (SGOC) was given to 128.8 g/kWh.

In this gas mode, 6.9 g/kWh of diesel oil was additionally consumed as the pilot oil to assist the initial ignition13).

The weight of the selected engines was estimated at 555 tons, whereas the weight of the scrubber system was at 9 tons. The electricity consumption for onboard installation was assumed at 0.5 MJ / system-weight11).

3.3 Results

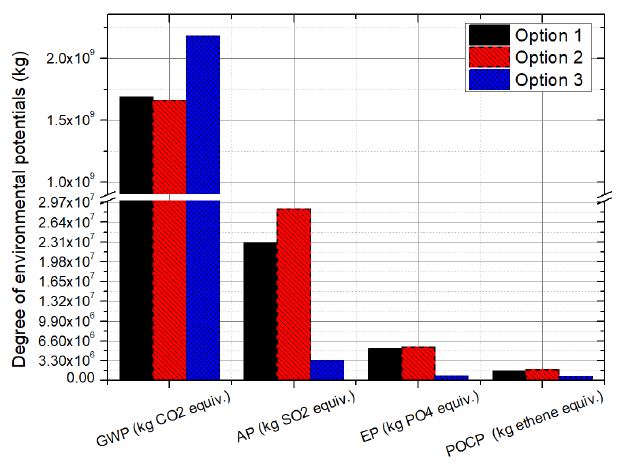

Using the LCA software, Gabi Version VI, the life cycle of the proposed options was modelled as shown in Fig. 6 where the global warming potential (GWP), acidification potential (AP), eutrophication potential (EP) and photochemical ozone generation potential (POCP) were evaluated in order to investigate the environmental impacts of such options.

According to Table 3 showing the results of the analysis, it was found that the environmental impacts associated with the operation stage dwarf those for construction and scrapping stage overall. The holistic environmental impacts of each option were compared in Fig. 7.

It revealed that Option 2 would produce relatively fewer emissions pertaining to GWP than other two options, while Option 3 would be cleaner in terms of AP, EP and POCP.

With regard to GWP, using LNG as a marine fuel was turned out to be the worst option: GWP for Option 3 was estimated at 2.18E+09 kg which was 0.51E+09 kg higher than Option 1, whereas 0.48E+09 kg higher than Option 2.

The results may be attributed to the fact that the LNG inherently contain the high level of methane that is critical to the GWP. On the other hand, in terms of AP, EP and POCP, the use of the scrubber system with HFO led to the highest emission level than others: it was estimated at 2.86E+07 kg for AP; 5.57E+06 kg for EP; 1.76E+06 kg for POCP.

It was because during the process of the heavy fuel oil refinery, relatively high level of emissions was produced, compared with the process of MGO or LNG refinery.

4. Discussion and conclusions

Indeed, given that the reliability of the LCA highly relies on the data quality, its collection when performing LCA is always problematic. This paper could be free from this issue. the analysis had to be somewhat simplified and assumptions needed to be applied to several parts. Meanwhile, the fact that environmental potentials cannot be technically compared one another leaves this paper incapable of suggesting the best option at all time.

Nevertheless, it is safely believed that the results of works done in this paper can provide insight into the environmental impact of the proposed options in the long-term view, expanding the awareness of the shipbuilders and owners toward the marine environmental protection. Research findings can be summarized as below:

a) Option 1, using MGO, would be effective in reducing GWP level, compared to using LNG, while better in reducing AP, EP and POCP levels than using HFO with the scrubber.

b) Option 2, using HFO with the scrubber system, would be the most desirable in terms of reducing the GWP level, whereas the least desirable in reducing AP, EP and POCP levels.

c) Option 3, using LNG as a marine fuel, would be the optimal option the most effective in curbing the AP, EP, and POCP levels.

d) LCA is proven to be an effective method to investigate the holistic environmental impact of marine systems.

e) For future study, various types of ships may need to be investigated to verify the adequacy of general application of the research findings.

Acknowledgments

The author would like to express his gratitude to the Department of Naval Architecture, Ocean and Marine Engineering in University of Strathclyde and Dr Jae-ung Lee, Mr Youngkyu Jo for their immeasurable supports.

References

- UNCTAD, (2015), "Review of Maritime transport", United Nations, Geneva.

- IMO, (2015), "Third IMO Greenhouse Gas Study 2014", IMO, London.

- F. Adamchak, and A. Adede, (2013), "LNG as marine fuel, 17th International conference and".

- Ship & Bunker, (2017), "World Bunker Prices".

- P. Semolinos, (2011), "LNG as marine fuel: challenges to be overcome", 17th International Conference & Exhibition on Liquefied Natural Gas, TOTAL Gas & Power, Houston, 2013.

- IGU, (2017), "2017 World LNG Report", IGU.

- M. Aymelek, E. Boulougouris, O. Turan, and D. Konovessis, (2014), "Challenges and opportunities for LNG as a ship fuel source and an application to bunkering network optimisation", Maritime technology and engineering, p767-776.

- M. D. Turbo, (2013), "Flexible Dual Future: MAN B&W ME-GI Engine".

- ISO, (2006), "Environmental Management Life Cycle Assessment Principles and Framework (ISO 14040: 2006)", The International Organization for Standardization Geneva,, Switzerland.

- ISO, (2006), "ISO 14044-2006. Environmental management–life cycle assessment–Requirements and Guidelines".

- H. Wang, E. Ouz, B. Jeong, and P. Zhou, (2017), "Optimisation of Operational Modes of Short-Route Hybrid Ferry: A Life Cycle Assessment Case Study", IMAM 2017 - International Maritime Association of the Mediterranean, Lisbon.

- J. Ling-Chin, O. Heidrich, and A. Roskilly, (2016), "Life cycle assessment (LCA)–from analysing methodology development to introducing an LCA framework for marine photovoltaic (PV) systems", Renewable and Sustainable Energy Reviews, 59, p352-378.

- Man Diesel & Turbo, (2014), "MAN B&W S70ME-C8.2-GI-TII Project Guide".